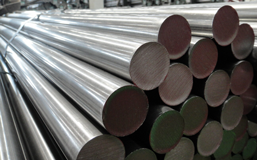

Cold drawing is a metal forming process whereby a piece of metal is forced through a single or series of dies, thereby reducing the cross section size of the original part. The cold drawing process yields a dimensionally consistent final product, while improving both yield and tensile strength. The resulting surface is clean and free from scale or other defects. Cold drawing is typically used to produce precision steel, copper and aluminum rods, bars and wire that must meet tight physical and mechanical specifications.

During the cold drawing process, a stationary platform called a drawing bench is used to hold the die in place. The bench has an in-feed and an out-feed side. The out-feed side consists of a long roller platform, used to catch the finished stock after it has been forced through the die. The metal stock, usually in bar or wire form, is loaded into the in-feed side. One end of the metal stock is reduced in size so it fits through the die. A hydraulic cylinder or winch is then used to pull the metal through the die and onto the out-feed rollers.