ABOUT SANGUAN STEEL

Established in 2007, Shenzhen Sanguan Special steel Co., Ltd is a professional exporter of special steel. Invested by Huangshi Weifeng New Material Technology Co.,Ltd and Sanli forging Co.,Ltd. We are located in Shenzhen city, with convenient transportation access.

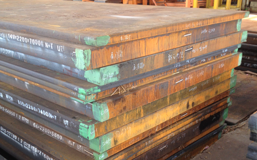

Sanguan Special Steels dominant products such as cold-work tool steel, hot- work tool steel, plastic mold steel, high speed steel, alloy structure steel, stainless steel which can provide services to coal, electricity, machinery manufacture, railway transportation and other industries. Moreover, we can offer forging and heat treating services, allowing us to provide bespoke sizes and unique shapes without charging a premium.

Sanguan Special Steels dominant products such as cold-work tool steel, hot- work tool steel, plastic mold steel, high speed steel, alloy structure steel, stainless steel which can provide services to coal, electricity, machinery manufacture, railway transportation and other industries. Moreover, we can offer forging and heat treating services, allowing us to provide bespoke sizes and unique shapes without charging a premium.

Equipment we use

-

Electroslag remelting (ESR), also known as electro-flux remelting, is a process of remelting and refining steel.Generally the ESR process offers very high, consistent, and predictable product quality. Finely controlled solidification improves soundness and structural integrity. Ingot surface quality is improved by the formation of a solidified thin slag skin between ingot and mold wall during the remelting operation.An electric arc furnace (EAF) is a furnace that heats charged material by means of an electric arcVacuum melting furnace utilizes electric currents to melt metal within a vacuum.Used for alloys which are subject to higher levels of stress, melting performed in a vacuum induction melting furnace makes it possible to not only improve the mechanical properties but also to assess the metal’s capability under hot deformation10TonsForging Hammer is widely accepted in modern open die forging plants, suitable for producing not only all kinds of steels,but also various open die forgings, such as shaft forgings, ring forgings, gear blanks, flanges etc.Centerless Lathe turning machine is suitable for processing all kinds of materials of round bars,it will makes the surface much more smooth than normal turning.

Any steel questions you might be having?

Any steel questions you might be having?

Looking for those"Hard to find "steel grades?

Get help from our professional team today!